Standards AWS A5.1 E7018

Chemical Composition of Weld Metal % (Typical) Si ≤0,75; Mn ≤1,6, S ≤0.035, P ≤0.040, Ni ≤0.30

Typical Base Material Grades S235JR-E295, E335, S235J2G3-S355J2G3, S235JRS1-S235J4S, S315G1S-S355G3S, S255N-S355N, S255NL-S355NL; C22, C35; P235T1-P355T1, P235T2, P355T2, P255NH-P355NH, P235G1TH, P255G1TH, P235GH-P295GH; L210-L360, L290MB-L360MB, API 5L: GrA, GrB, X42, X46, X52, X56, X60; GE200-GE300

Mechanical Properties Yield Strength (N/mm²) min. 482; Tensile Strength (N/mm²) min. 399; Impact Strength (ISO-V/-40°C) min. 47 J; Elongation ((Lo=5do) (%)) min. 22

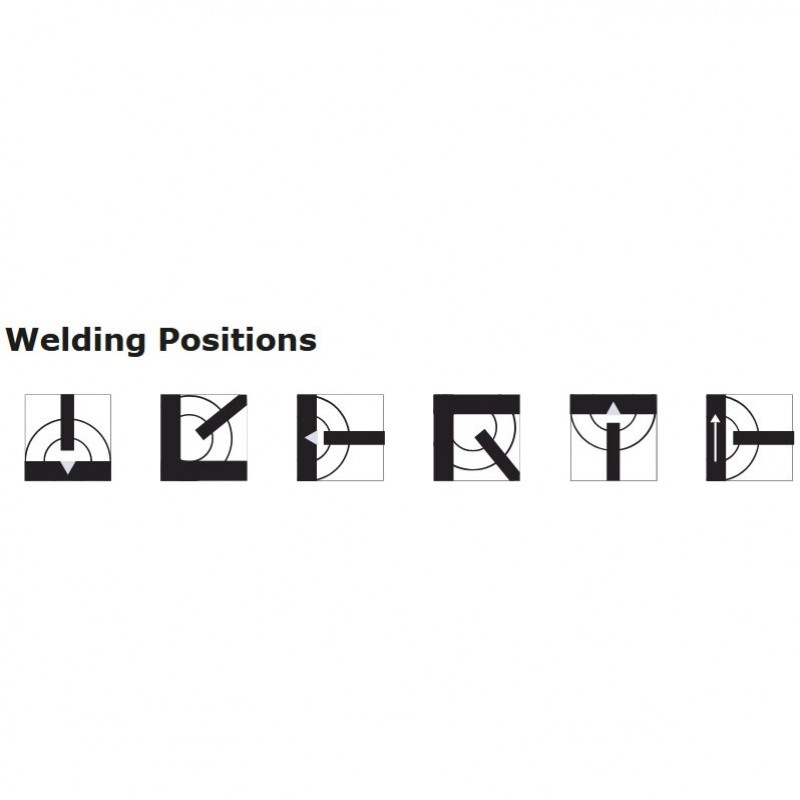

Features and Applications Suitabilty for use in out-of-position welding except for welding at vertical down position; Excellent strength and toughness; Suitability for the formation of welding buffer layers when building up high-carbon steels; Weld deposits with very low hydrogen content; Weld metal recovery of about 120%.; Requirement of re-drying for minimum 2 hours at the temperatures between 300°C and 350°C

Current Type DC(+)

Approvals ABS BV CCS DNV GL LR NK RINA CE DB

|

Product Code

|

Diameter x Lengh

|

Welding current (A)

|

|

E701825350W

|

ø2,5 x 350 mm (ø3/32 x 14)

|

60 - 100

|

|

E701832350W

|

ø3,2 x 350 mm (ø1/8 x 14)

|

80 - 140

|

|

E701840400W

|

ø4,0 x 400 mm (ø5/32 x 16)

|

110 - 210

|

|

![]()

![]()

-228x228.jpg)